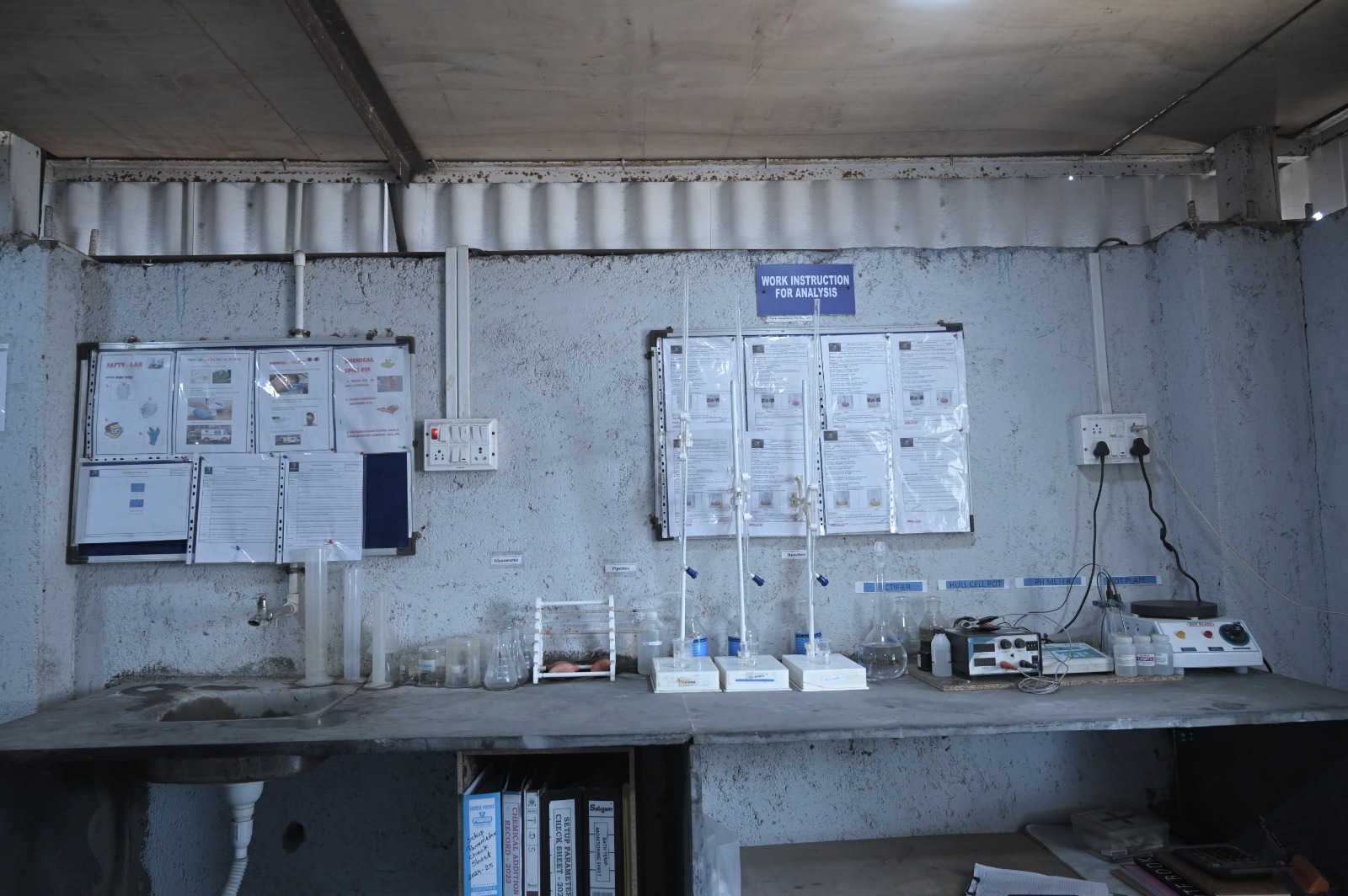

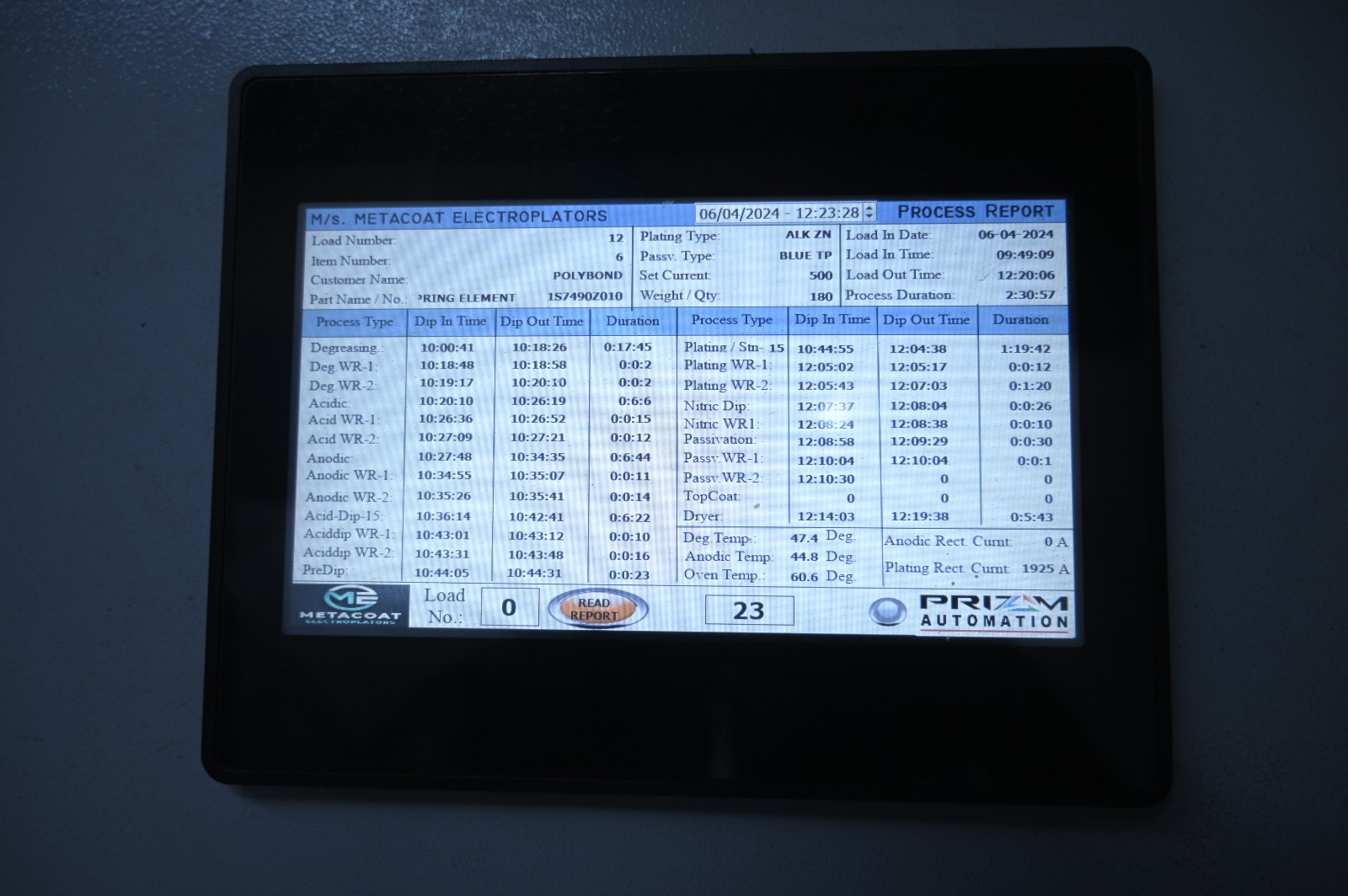

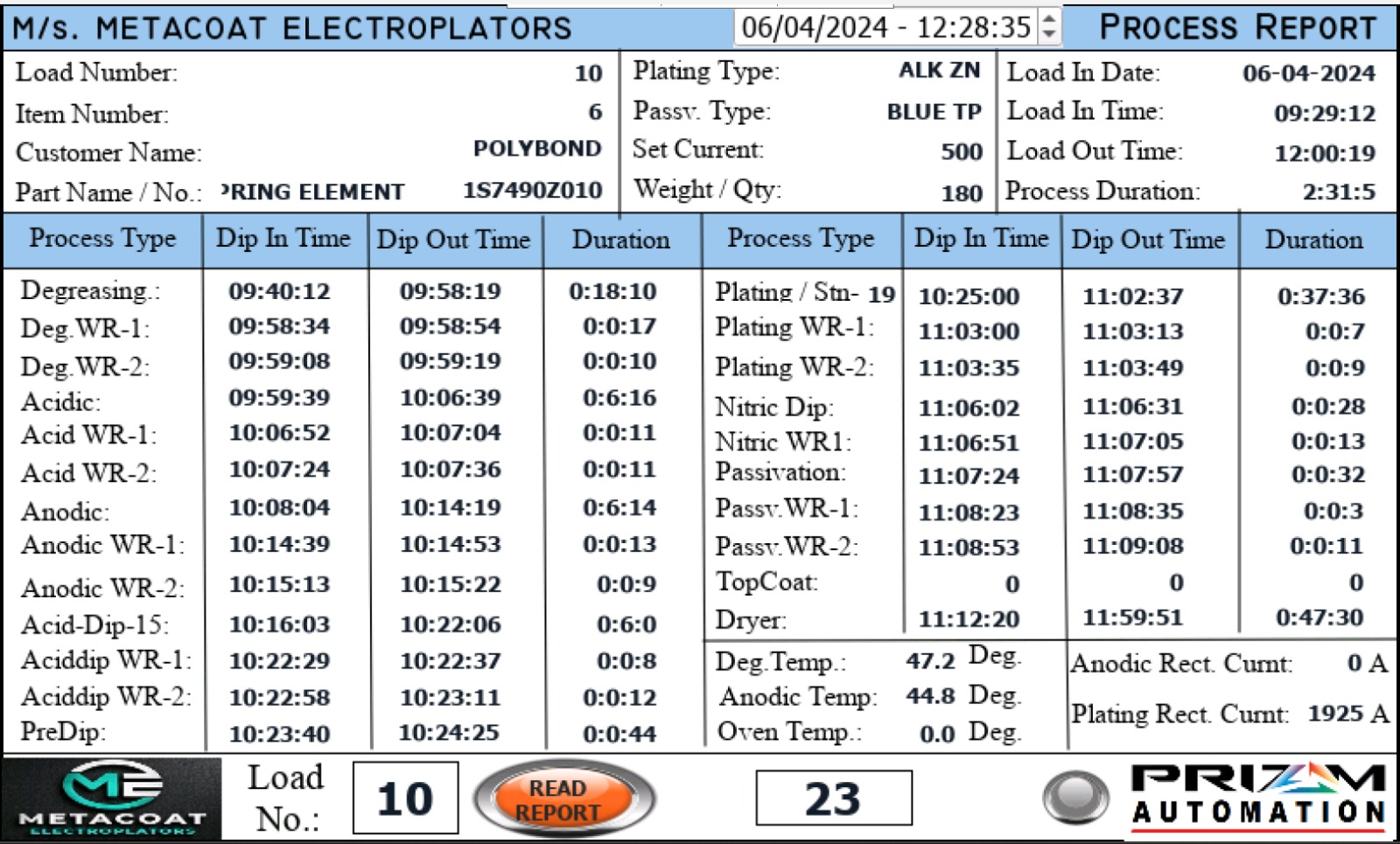

Electroplating

Electro plating stands as a meticulously orchestrated process, where a thin layer of metal

is delicately applied onto another metal or conductive surface through the intricate method

of electro-deposition. This technique ensures a seamless integration of the deposited metal

into the substrate, resulting in enhanced durability and an elevated aesthetic appeal. Widely

recognized for its multifaced applications, electroplating serves not only as a means of

adornment for decorative purposes but also as robust protective barrier against the corrosive

forces of rust, moisture, and environmetal degradation. In essence, electroplating emerges as

a vital safeguard, fortifying components and surfaces with an enduring shield. Thereby prolonging

their lifespan and maintaining their structural integrity amidst various environmental challenges.